Diecasting in Malaysia has actually ended up being a keystone of the country’s manufacturing industry, functioning as a crucial element in industries such as automotive, electronic devices, and durable goods. This highly specialized procedure includes infusing molten steel into a mold and mildew cavity under high stress, producing elements with remarkable accuracy and sturdiness. The increase of diecasting in Malaysia is credited to the country’s commitment to development, competent workforce, and tactical location, which make it an attractive hub for global production. As markets continue to require light-weight, high-performance elements, diecasting in Malaysia is playing a critical function in meeting these needs effectively and sustainably.

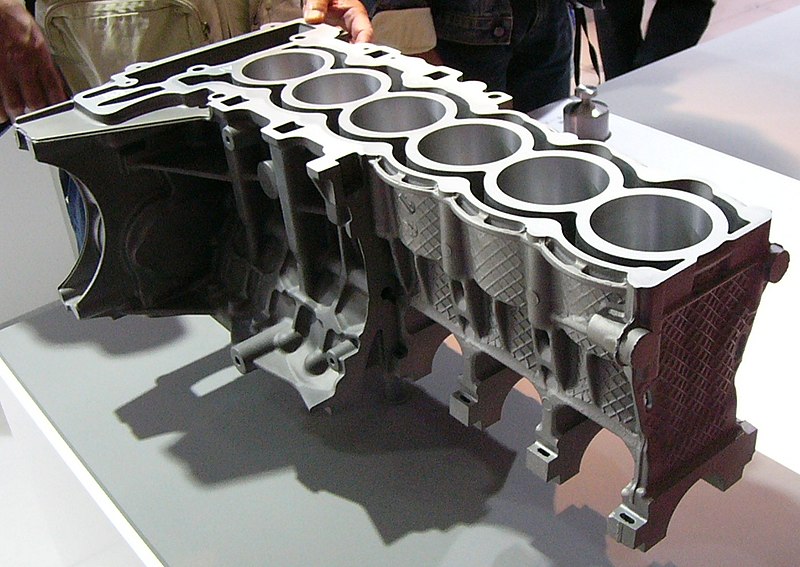

Among the crucial strengths of Malaysia’s diecasting industry is its capacity to produce detailed and high-quality elements. Light weight aluminum, zinc, and magnesium are one of the most generally made use of products in diecasting, known for their lightweight buildings and structural integrity. Malaysian makers utilize progressed equipment and techniques to make sure constant top quality and dimensional precision, making their parts very sought after in worldwide markets. This precision is especially vital in the vehicle industry, where diecast components such as engine blocks, transmission situations, and brackets need to meet rigorous safety and efficiency requirements. By regularly delivering excellence, Malaysia has developed itself as a trusted name in the international diecasting sector.

The electronic devices industry in Malaysia additionally benefits substantially from diecasting, as it allows the production of parts with complex geometries and slim wall surfaces. These qualities are necessary for making parts utilized in customer electronics, telecoms, and industrial tools. Warm sinks, rooms, and ports are among the diecast products that play a pivotal function in preserving the performance and performance of electronic gadgets. Malaysia’s concentrate on technological advancement and adherence to global quality standards have made it a favored location for electronics business seeking dependable diecasting solutions. This synergy in between diecasting and electronic devices highlights the flexibility and relevance of the market.

Sustainability is ending up being a significantly substantial facet of precision die casting Malaysia, as markets worldwide prioritize environment-friendly manufacturing techniques. Diecasting is inherently reliable, with very little product wastefulness due to the recyclability of metals like aluminum and zinc. Malaysian suppliers are taking on eco liable techniques, such as energy-efficient machinery and closed-loop recycling systems, to minimize their carbon footprint. This commitment to sustainability not just aligns with international ecological goals but also improves the competition of Malaysia’s diecasting sector in an age where eco-friendly manufacturing is a vital differentiator.

An additional variable adding to the growth of diecasting in Malaysia is the country’s critical concentrate on development and ability development. Federal government campaigns, such as tax obligation incentives for innovation adoption and grants for research and development, have actually encouraged manufacturers to purchase advanced tools and processes. At the exact same time, technological training programs and collaborations with educational institutions have aided grow a competent labor force capable of running innovative machinery. This emphasis on development and competence makes sure that Malaysian diecasting companies continue to be affordable in a quickly developing industry, attracting both neighborhood and international clients.

Diecasting in Malaysia stands as a testimony to the country’s production prowess, combining accuracy, technology, and sustainability to fulfill the demands of global industries. With its capability to produce high-quality components for auto, electronics, and various other sectors, Malaysia has earned a reputation as a trustworthy and forward-thinking player in the diecasting industry. The assimilation of green practices and continuous financial investment in technology and skills further enhances the nation’s setting in the international market. As the need for light-weight, sturdy, and lasting elements continues to grow, Malaysia’s diecasting market is positioned to play an even better role fit the future of manufacturing.